|

How to improve your trigger function

by

installing an overtravel stop in both

pull and release.

Tools and equipment needed:

An acetylene or mapp torch, silver solder, epoxy glue or

Loctite, a drill and drill bits, suitable pieces of brass

tubing/rod and plate, needle files, needle nose pliers, a

couple of screwdrivers to aid in assembly / disassembly. A

lathe is preferable if available. Otherwise the sleeve

part will need to be outsourced.

If you assemble your

trigger mechanism

incorrectly it might cause misfires,

or other malfunctions. Beware that the only safety device

in the triggergroup is that the trigger is blocked.

Altering the shape of any of these parts or removal of

material *might* render the trigger mechanism unusable at

best, or right out dangerous in worst case.

If

you choose to proceed, you do this on your own risk, and

if you somehow manages to break or otherwise ruin your

trigger mechanism or parts thereof, well that is your problem. If you are not 100% sure

that you can manage to do this, don't do it, or pay

someone competent to do it for you.

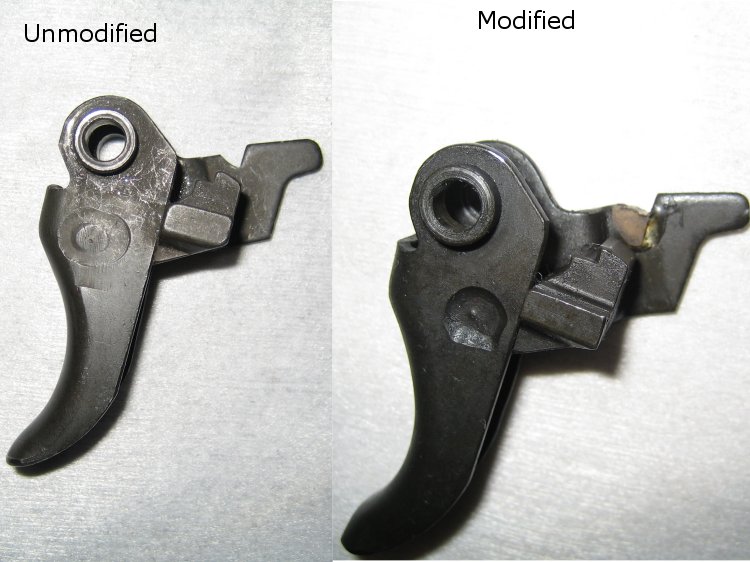

1.

Modifying the trigger.

This modification will remove rearwards overtravel.

The modification consist of silver

soldering a piece of brass to the notch in the trigger

that is engaged by the safety selector.

It can of course be welded steel, but I found it easier to

use silver solder/brass

due to it requires less heat, and the brass is easier to

shape when fitting the pieces together afterwards. Be

careful when applying heat so that the heat treated parts

engaged by the sear don't get too hot.

Fitting:

File the brass piece down in small increments to the

point that trigger travel ends just after the hammer is

released. To find this point will more than probably

reqiure that the trigger mechanism is assembled and

disassembled several times.

Test the trigger action several times to make sure the

trigger releases the hammer each time it is pulled.

Note that this modification will remove the full auto

function if done to a FA trigger mechanism, as the FA

function needs the longer trigger travel to hold the sear

clear of the notch in the hammer.

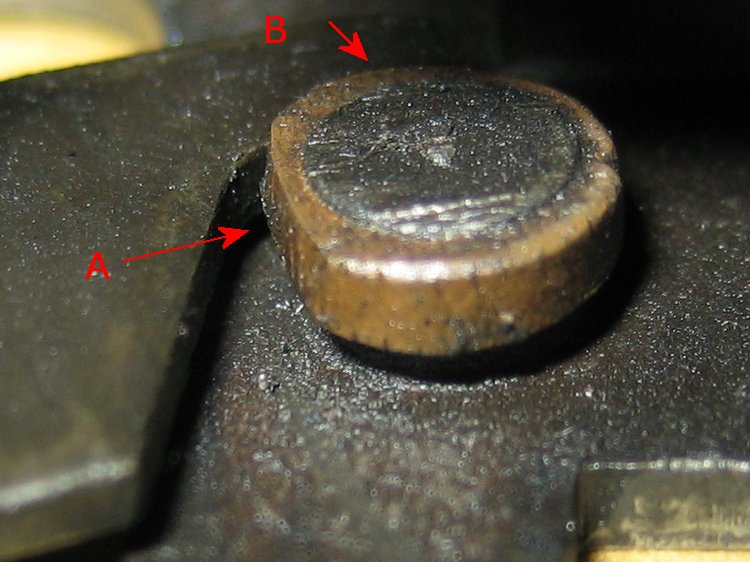

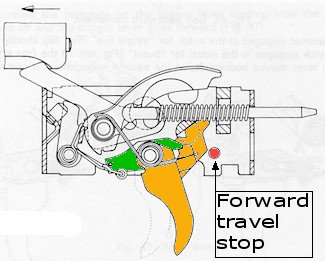

2.

Modifying the trigger housing.

This modification will remove the forward overtravel.

This modification consist of making a

brass sleeve for the forward travel stop bolt. The sleeve

itself has an outside diameter of appx. 6.5 milimeters and

an inside diameter of 5.0 milimeters. The length should be

about 2.5 - 3.0 milimeters.

Fitting:

Remove material from the

area

A

in the above pic

in small increments to the point that

it don't impede on trigger rearward

travel.

To find this point will more than probably reqiure the

sleeve to be removed and installed several times.

Remove material from the

area

B

in the above pic

flat in small increments to the point that trigger

forward travel ends just after the sear engages the

trigger. This is easibly recognised by an audible "click".

To find this point will more than probably reqiure the

sleeve to be removed and installed several times.

Test the trigger action several times to make sure that

sear engages the trigger each time. When the trigger

functions flawlessly, attach the sleeve with epoxy glue,

Loctite 640/660 or similar.

Another trick is to use an MP5 trigger spring in the G3 to

get a lighter trigger pull,

but this will normally cause the odd misfire in surplus

ammo due to the hard primers used in military ammo. This

modification should work fine with commercial ammo with

softer primers. |